The Best Guide To Aws Cwi

Table of ContentsThings about Aws CwiThe Ultimate Guide To Aws CwiLittle Known Questions About Aws Cwi.Everything about Aws CwiFascination About Aws Cwi

Have you ever thought about a job as a welding inspector? A welding assessment qualification is not just a great accomplishment, it confirms your capabilities in the welding sector.

Coming To Be a Licensed Welding Assessor shows your dedication to expanding within the welding sector. This certification is one that must not and will not be overlooked! As a CWI, you'll be able to benefit from a variety of various possibilities amongst market professionals.

Licensed Weld Inspectors are an extremely valuable and important asset for steel fabricators. Their visibility is rather advantageous for any kind of company working with the makers that bring them on board. As you might know, welding is among one of the most intricate services within the metal construction sector. The end result of every welding project is very reliant upon private welder skill.

The smart Trick of Aws Cwi That Nobody is Talking About

There's no question that CWIs help to maintain greater degrees of consistency and high quality to the welding divisions they oversee. This blog post gives a short overview of the primary benefits of working with a metal construction company that utilizes certified weld inspectors. It's not shocking that a lot of prominent sectors will certainly need you to employ licensed welding examiners to look after welding.

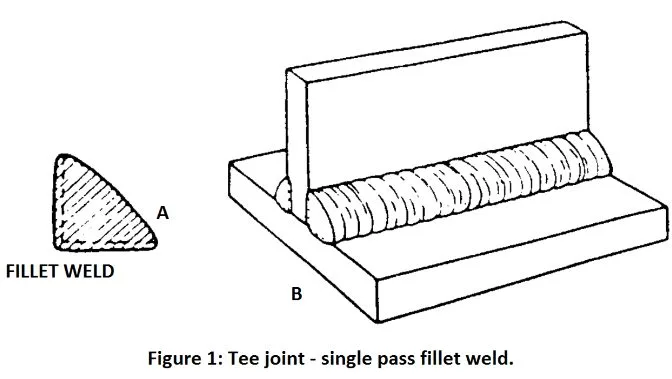

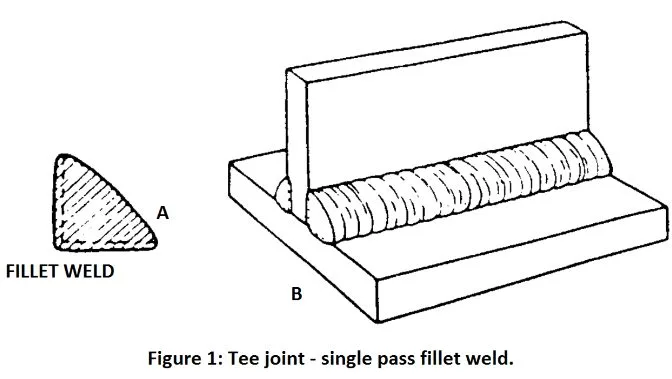

Licensed welding examiners have years of experience and thus, they comprehend the subtleties of compliance with welding codes. Complying with the welding process, CWIs can conduct a collection of test to examine the quality of a weld, consisting of aesthetic evaluation, heat treatment and a hydrostatic test. Certified Welding Inspector. They can likewise make the correct adjustments to the pre-weld preparation and the in-weld procedures as essential

An internal licensed welding assessor will be able to guarantee that your task is customized to all the requirements of relevant welding codes, ensuring its high quality. Welding inspectors can review welding treatment specs, structure and welding strategies, tools calibration and welding products. A welding examiners capacity to supply welding treatment requirements offers the steel fabrication business a significant side of the competition, permitting fabricators to design welds that ideal suit private components, rather of using reliable welds.

How Aws Cwi can Save You Time, Stress, and Money.

As formerly mentioned, a CWI is not just accountable fore creating the treatments for the weld, yet also the browse around here quality-check screening procedures. https://myspace.com/awscw1w3lding. Past that, welding inspectors work to guarantee that devices is appropriately prepped for the job which welders are able to finish their welds with skills (Weld Inspector). A certified welding inspector will certainly have had years of experience, which a steel manufacture firm can utilize to make certain outstanding results for all fabrication projects that involve welding

This is why it's critical to locate a welding firm with a skilled and highly trained in-house licensed welding inspector on personnel. Thankfully, CAMM metals is such an organization, so call us today if you have a forthcoming project that needs top quality custom-made welding! It's clear that a personalized steel construction supplier with in-house CWIs has committed to investing in the high quality of its welds.

Some industries require CWIs to be included in the production of components. In the long run, CWIs presume a fair bit of obligation, yet their experience shows in the end product. Below at CAMM Metals, after the welding portion of the task is total, we provide many internal solutions. These solutions include weld evaluation with dye penetrant, acid cleaning and polishing of stainless steel welds.

For those customers that require certified welds, we can accredit our welds to AWS D1.1 & AWS D1.6.

Getting The Aws Cwi To Work

It is necessary to keep in mind that lots of employers do not constantly need welders to be licensed. Some only ask that work applicants pass a welder performance certification prior to employing them. In this circumstance, those who pass the test would be taken into consideration "certified welders," not "licensed welders." The primary difference is that licensed welders have actually written documents of their test outcomes and their efficiency is regularly monitored with regular assessment( s) becoming part of the efficiency document for each welder.

Before taking the examination all PFS welders are educated, if required, in the actual welding process that they will be utilizing and they will need to have a functioning understanding of the welding equipment, welding consumable and the material to be welded. Efficiently passing one test will enable the welder to work with many sorts of manufactures Will not permit him to work on all types of fabrication as there are qualification ranges enforced for each examination configuration.

Crucial variables consist of yet are not limited to material kind, palatable type, material thickness and welding setting. etc. After the welder has finished his examination plate or pipe the weld is checked utilizing the complying with NDE processes: Visual Assessment X-Ray Liquid Penetrant Testing In some instances, the weld is also destructively evaluated.

Rumored Buzz on Aws Cwi

PFS accomplishes this utilizing a connection record that details all welds that a welder makes. If a welder does not make use of the welding procedure in a 6-month period, then they will be requalified because procedure. The benefits to making use of a qualification system are lots of yet the significant advantages are: It verifies the ability of an individual to perform in conformity with a certified welding procedure requirements (WPS) to generate a good weld.

Comments on “The Greatest Guide To Aws Cwi”